How to Choose the Right Battery Size for a 2000 Watt Inverter

Choosing the right battery size for a 2000 watt inverter is crucial for ensuring efficient operation and adequate power supply. A common recommendation is to use at least a 100Ah battery, but larger capacities may be necessary depending on your specific power needs. Understanding these requirements will help you optimize your setup effectively.

What is the recommended battery type for a 2000W inverter?

The recommended battery types for a 2000W inverter include lead-acid batteries (such as AGM or deep-cycle) and lithium-ion batteries. Lithium batteries are preferred for their higher energy density, lighter weight, and longer lifespan, while lead-acid batteries are more economical and widely available. For a 2000W inverter, several types of batteries can be used, including:

- Lead-Acid Batteries: Economical but heavier and require regular maintenance.

- Lithium-Ion Batteries: Lightweight, longer lifespan, and higher discharge rates, making them ideal for high-demand applications.

- Nickel-Metal Hydride Batteries: Suitable for lighter loads but less common in high-capacity setups.

Among these options, lithium-ion batteries are increasingly favored due to their efficiency and longevity.

| Battery Type | Description |

|---|---|

| Lead-Acid | Cost-effective but heavy and requires maintenance. |

| Lithium-Ion | Lightweight, long-lasting, and high discharge rates. |

| Nickel-Metal Hydride | Good for lighter loads but less common in high-capacity setups. |

How many Ah battery should be paired with a 2000W inverter?

For a 2000W inverter, a minimum battery capacity of 200Ah is recommended. This ensures sufficient power supply for typical usage scenarios. Depending on the desired runtime and load requirements, capacities may need to be higher, especially for longer usage periods. For optimal performance, especially if you plan to run high-wattage devices continuously, consider using:

- 200Ah or higher capacity batteries to ensure adequate power supply without significant voltage drops.

Using the formula:

For example, if running at 12V:

This calculation indicates that at least 166.67Ah would be needed to run the inverter at full capacity for one hour.

| Recommended Capacity | Description |

|---|---|

| Minimum of 100Ah | Suitable for short-term use under low loads. |

| Ideally 200Ah or more | Better suited for continuous operation and higher loads. |

What factors should you consider when selecting a battery for a 2000W inverter?

Consider factors such as battery type, capacity (Ah), discharge rate, and voltage compatibility with the inverter. Additionally, evaluate the expected runtime, efficiency losses, and the specific power demands of the devices you plan to run. When selecting a battery, consider:

- Depth of Discharge (DoD): Lithium batteries can typically be discharged deeper than lead-acid batteries without damage.

- Charging Time: Lithium batteries usually charge faster than lead-acid options.

- Weight and Size: Ensure that your chosen battery fits your space and weight constraints.

- Cost vs. Performance: Balance your budget against the performance benefits of different battery types.

| Factor | Description |

|---|---|

| Depth of Discharge | Affects how much usable energy you can extract. |

| Charging Time | Impacts downtime between uses. |

| Weight and Size | Must fit within your setup’s physical constraints. |

| Cost vs. Performance | Evaluate based on your budget and energy needs. |

How can you calculate the required battery capacity for a 2000W inverter?

To determine the necessary capacity, use this formula:

For example, if you want to run a 2000W load for 2 hours using a 12V system with a DoD of 50%, the calculation would be:

This means you would need approximately 667Ah of total capacity to sustain that load efficiently.

| Calculation Example | Description |

|---|---|

| Power Requirement | Total watts needed multiplied by runtime hours. |

| Voltage Consideration | Adjusting calculations based on system voltage. |

| Depth of Discharge | Ensures safe usage without damaging the battery. |

Why is it important to match the battery type with the inverter?

Matching the battery type with the inverter is crucial for optimal performance and safety. Different batteries have varying discharge rates and efficiencies; using an incompatible type can lead to poor performance, overheating, or damage to both the battery and inverter. Matching the right battery type with your inverter ensures optimal performance and longevity:

- Different batteries have varying discharge rates and efficiencies; mismatching can lead to inadequate power supply or damage.

- Lithium batteries provide higher efficiency and longer life spans compared to traditional lead-acid types.

- Using compatible components minimizes risks associated with overheating or overloading.

| Importance | Description |

|---|---|

| Optimal Performance | Ensures efficient energy use and longevity of components. |

| Risk Minimization | Reduces chances of overheating or damage from mismatched systems. |

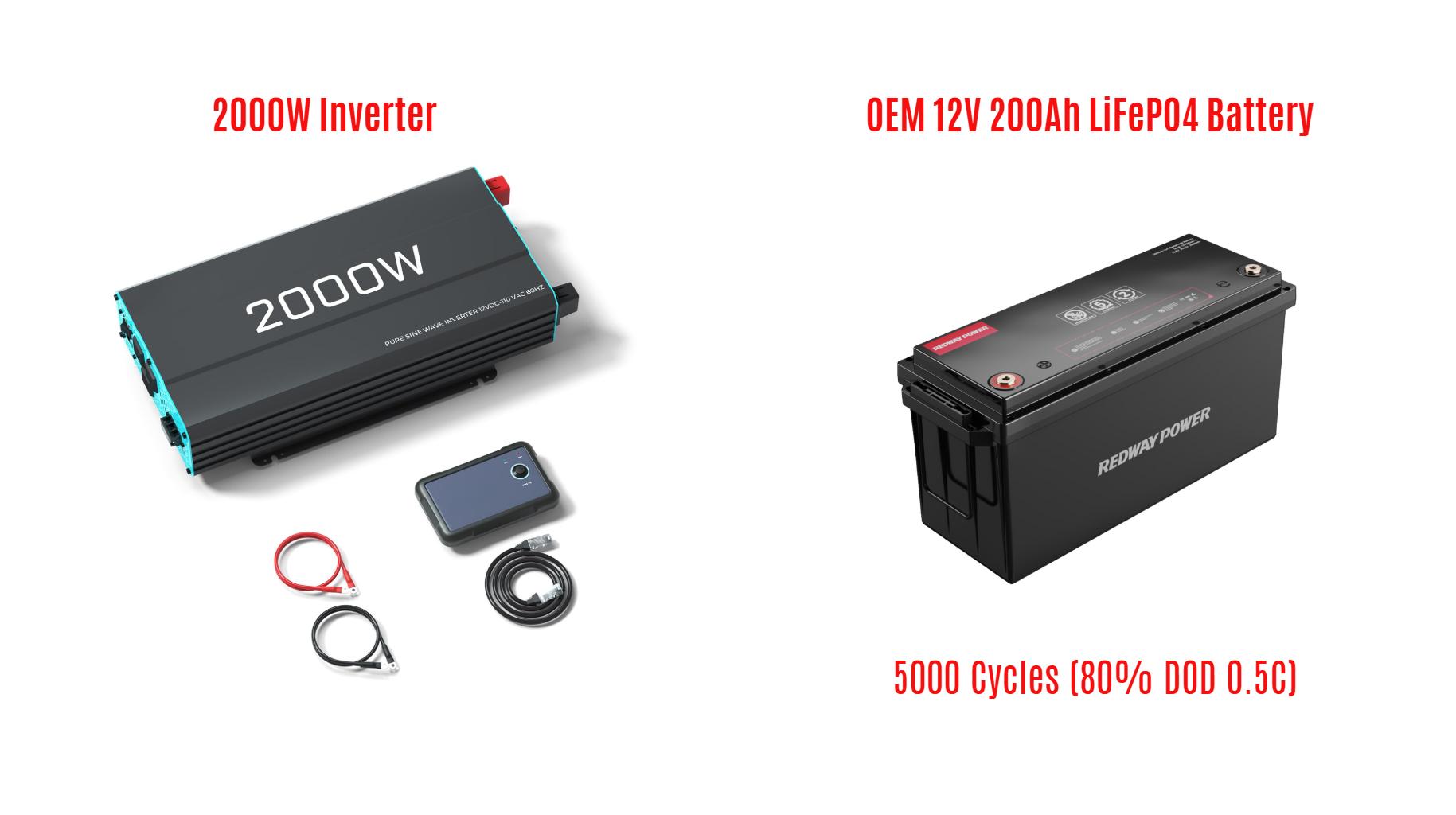

OEM Tips

When considering OEM orders for batteries or inverters, it’s essential to partner with reliable manufacturers like Redway Battery. With over 13 years of experience, Redway specializes in high-quality lithium batteries that serve as excellent alternatives to traditional lead-acid options. Their products offer enhanced performance and longevity, making them ideal for powering devices effectively in various applications.

LiFePO4 Battery Expert Views

Choosing the right combination of batteries and inverters is crucial,” says an expert in lithium technology. “Understanding your power needs and selecting appropriate components ensures not only efficiency but also safety during operation.” This insight emphasizes careful planning when setting up power systems.

How Many Batteries To Power 2000w Inverter?

To power a 2000W inverter, you typically need at least two 12V batteries connected in parallel. This setup provides enough current for the inverter’s peak demand. Ensure the combined amp-hour rating of the batteries meets your power needs for the desired duration of use.

FAQ Section

Q: Can I use a smaller capacity battery with my 2000W inverter?

A: While it’s possible, using a smaller capacity may result in insufficient power supply and reduced runtime.Q: What happens if I exceed my battery’s depth of discharge?

A: Exceeding DoD can damage your battery over time, reducing its lifespan and performance.Q: Is it better to use lithium or lead-acid batteries?

A: Lithium batteries are generally preferred due to their efficiency, lighter weight, and longer lifespan compared to lead-acid options.